- carbon crystal panel

- artificial stone

- Stone plastic wall panel

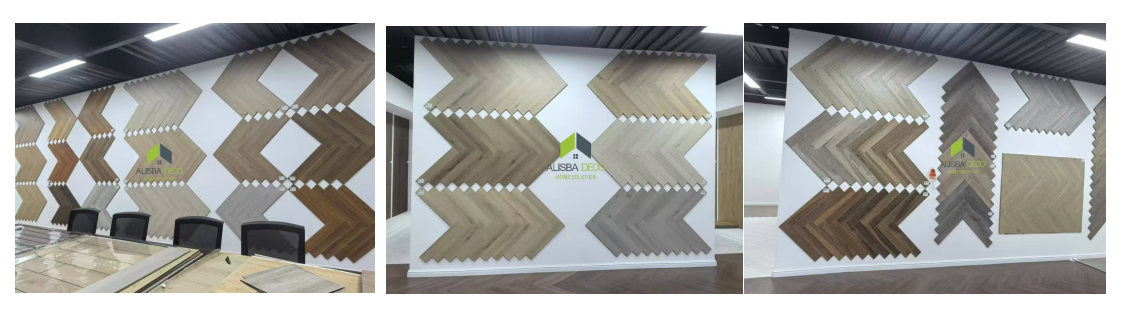

- Fish Bone Laminate Flooring

- self-adhesion wall sticker

- herringbone Floor

- High customer satisfaction: High quality products win praise

- About rhe SPC Flooring

- About Soft Stone Products

- Have a good news

- News from wall panels

- Industry news

How to adjust the herringbone floor after installation

After the installation of the herringbone floor, there may be some issues such as flatness, splicing gaps, and abnormal noise that need to be adjusted accordingly

Flatness adjustment

Local protrusion treatment: If local protrusions are found on the floor surface, first determine the cause of the protrusions. If the floor is not fully adhered to the base layer during splicing, a rubber hammer can be used to gently tap the raised area to ensure full contact with the base layer. If the floor is lifted up by small particles of debris on the base layer, be careful to lift the floor in that area, clean up the debris on the base layer, and then lay it again to ensure a tight fit.

Partial depression repair: For cases of partial depression, if the degree of depression is mild, a thin gasket such as cardboard or thin wood can be placed below the depression to raise the floor to be level with the surrounding area. If the depression is severe, it is necessary to check whether the base layer is damaged. If there is any damage, the base layer should be repaired and the floor in the area should be re laid.

Splicing gap adjustment

Excessive gap treatment: When the joint gap is greater than the normal standard, try using specialized floor repair glue to fill the gap. First, clean the gap to remove dust and debris, then evenly inject the repair glue into the gap, scrape it flat with a scraper, wait for the glue to dry and solidify, and then polish it flat. If the gap is too large due to inadequate floor splicing, a tool (such as a pry bar) can be used to carefully pry the floor to make it tightly spliced and reduce the gap.

Uneven gap repair: For uneven splicing gaps, start from the end with the larger gap and adjust the floor position in sequence. Gently pry the floor and move it towards the direction with smaller gaps, gradually making the gaps uniform and consistent. During the adjustment process, it is important to avoid excessive prying that may cause damage to the floor or loose joints.

Adjustment of abnormal noise problem

Search for the source of the abnormal noise: Walk slowly on the floor and carefully identify the location and characteristics of the noise. Determine whether the abnormal noise is caused by friction between the floor and substrate, friction between floors, or other reasons.

Targeted solution: If there is a gap between the floor and the base layer causing friction noise, an appropriate amount of floor specific filling adhesive can be injected into the gap to fill it and reduce friction. If there is abnormal noise caused by friction between floors, a small amount of floor wax or lubricant can be applied to the gaps to reduce friction and eliminate the noise.

Color and appearance adjustment

Minor color difference treatment: If slight color difference is found on the floor after installation, it can be adjusted by waxing or painting. Choosing floor wax or paint that is similar in color to the floor and evenly applying it to the surface of the floor can reduce the visual effect of color difference to a certain extent.

Stain and scratch repair: For stains on the floor surface, choose the appropriate cleaning agent according to the type of stain for cleaning. For minor scratches, a specialized floor repair pen or repair paste can be used to repair them. After application, polish and polish the floor to restore its smoothness.