- carbon crystal panel

- artificial stone

- Stone plastic wall panel

- Fish Bone Laminate Flooring

- self-adhesion wall sticker

- herringbone Floor

- High customer satisfaction: High quality products win praise

- About rhe SPC Flooring

- About Soft Stone Products

- Have a good news

- News from wall panels

- Industry news

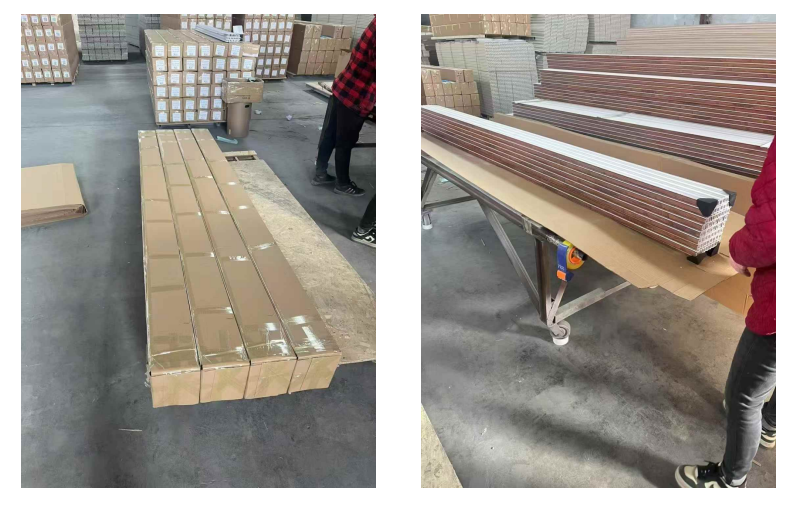

Purpose of packaging and boxing with wall panel and corner protector

The main purpose of packaging and boxing with wall panel and corner protectors is as follows:

Protecting products

Preventing corner damage: During the handling, loading, unloading, and transportation of wall panel, corner areas are highly susceptible to damage due to collisions and friction. Corner guards are usually made of materials with certain strength and toughness, such as paper, plastic or foam materials. They can form a protective barrier at the corners of the wall panel, absorbing and dispersing the impact force generated by collisions, avoiding problems such as cracking, paint peeling, and wear at the corners of the wall panel, and ensuring the integrity of the product's appearance.

Avoiding overall deformation: Adding corner protectors not only protects the edges of the wall panel, but also provides some support and reinforcement to its overall structure. When subjected to external pressure, the corner guard can share some of the pressure, prevent the wall panel from twisting or deforming due to uneven force, and ensure the shape and dimensional accuracy of the wall panel, so that it can still be used and installed normally after reaching its destination.

Reduce internal damage: The packaging box can further protect the wall panel from external impacts and vibrations. During transportation, vehicle bumps, collisions during handling, and other factors may cause damage to the wall panel. The buffer space and corner protectors inside the packaging box can effectively buffer these external forces, reduce the risk of damage to the internal structure of the wall panel, and ensure that the quality of the wall panel is not affected.

Convenient transportation and storage

Easy to transport: After corner protection and packaging, the overall packaging of the wall panel is more organized, making it easier for workers to use forklifts, pallet trucks, and other equipment for handling operations. The regular packaging shape and stable structure can improve handling efficiency and reduce the risk of safety accidents caused by non-standard packaging during the handling process.

Beneficial for stacking: In the cargo hold of warehouse storage or transportation vehicles, neatly packaged wall panel is easier to stack and arrange. Corner protectors can enhance the stability of packaging, prevent the grid from collapsing during stacking, fully utilize storage space, and improve the space utilization of storage and transportation.

Adapting to logistics environment: The modern logistics transportation process is complex, involving the conversion of multiple transportation modes and different storage conditions. The wall panel with corner protection packaging can better adapt to different logistics environments, whether it is bumpy road transportation, high vibration railway transportation, or warehouse storage with large humidity changes, it can protect products from damage to the greatest extent and ensure safe delivery to customers.

Enhance customer experience

Product integrity: When customers receive wall panel products with intact packaging and no damage, they will have a good impression of product quality and corporate service. This helps to improve customer satisfaction and loyalty, and establish a good brand image for the enterprise.

Easy to inspect: Standardized packaging makes it more convenient and efficient for customers to inspect goods. Clear packaging labeling and complete product protection measures allow customers to visually see that the product has been properly taken care of during transportation, reducing disputes and returns caused by product damage and improving transaction efficiency.