- carbon crystal panel

- artificial stone

- Stone plastic wall panel

- Fish Bone Laminate Flooring

- self-adhesion wall sticker

- herringbone Floor

- High customer satisfaction: High quality products win praise

- About rhe SPC Flooring

- About Soft Stone Products

- Have a good news

- News from wall panels

- Industry news

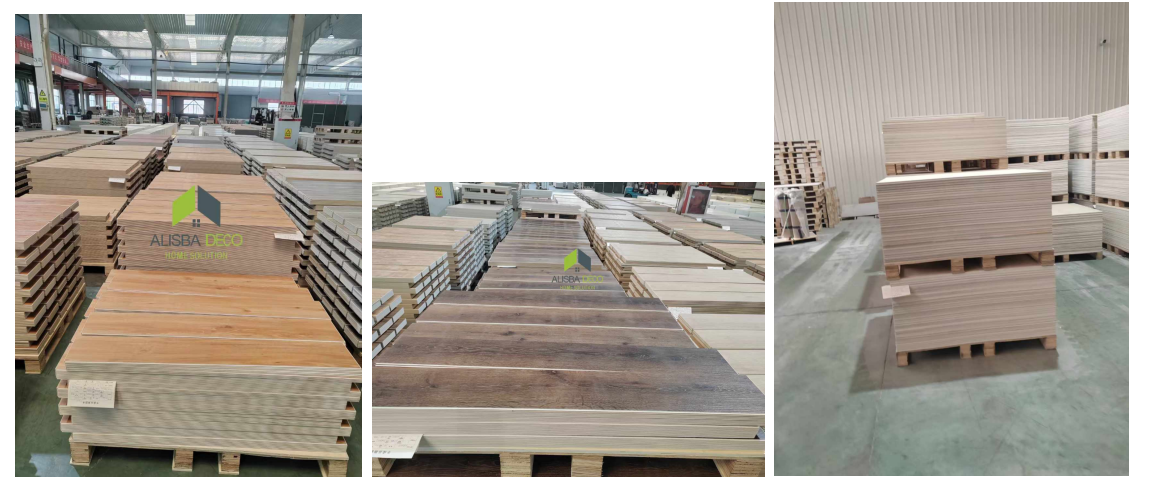

SPC Flooring in production

SPC (Stone Plastic Composite) flooring combines the benefits of rigid core stability and luxury vinyl top layer, offering high durability and water resistance. Its production involves a series of precise stages to ensure quality and consistency. Here’s an overview of the manufacturing process:

Step 1: Material Preparation

Sourcing Ingredients: High-quality PVC resins, calcium carbonate (for rigidity), stabilizers, and pigments are sourced and mixed according to formulation requirements.

Step 2: Mixing and Compounding

Compounding Ingredients: The raw materials are compounded in industrial mixers until a homogenous mixture is achieved. This ensures consistent color and mechanical properties across batches.

Step 3: Extrusion

Forming Sheets: The compounded material is fed into an extruder where it’s heated and formed into sheets. This stage defines the thickness and initial structure of the SPC core layer.

Step 4: Cooling and Calendering

Cooling: The hot extruded sheet passes through cooling rollers to solidify and stabilize its shape.

Calendering: The sheet is further pressed to achieve a smooth and uniform thickness.

Step 5: Print Layer Addition

Digital Printing: A high-definition image layer is applied onto the cooled SPC core to mimic wood, stone, or other designs. This creates the decorative aspect of the flooring.

Step 6: Lamination

Sealing Image Layer: A wear-resistant clear protective layer (wear layer) is added to protect the print layer from scratches and abrasion.

Step 7: Cutting and Profiling

Precision Cuts: The continuous sheet is cut into individual planks based on desired dimensions such as 1220x182x4mm.

Beveling Edges: If required, beveled edges are created for enhanced realism and easier installation.

Step 8: Backing Attachment

Acoustic Layer: An additional backing layer, often made of foam, is attached for noise reduction and comfort underfoot.

Step 9: Quality Control

Inspection: Each piece undergoes rigorous checks for defects like color inconsistency, thickness variations, and structural integrity.

Step 10: Packaging

Packaging: Planks are grouped, labeled, and packed ready for distribution.

Throughout the process, strict adherence to environmental standards ensures minimal waste and emission control. Modern SPC flooring production leverages automation and robotics for efficiency while maintaining high quality.

From concept to completion, every step is designed to produce durable, aesthetically pleasing flooring that meets consumer demands for modern living spaces.