- carbon crystal panel

- artificial stone

- Stone plastic wall panel

- Fish Bone Laminate Flooring

- self-adhesion wall sticker

- herringbone Floor

- High customer satisfaction: High quality products win praise

- About rhe SPC Flooring

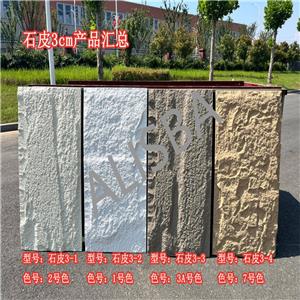

- About Soft Stone Products

- Have a good news

- News from wall panels

- Industry news

We loaded 2 Containers of UV board today

Loading two Containers of UV board is an important logistics activity, marking the smooth transition of products from the production stage to the distribution stage. UV board are widely used in home decoration, commercial space decoration and other fields due to their surface being treated with ultraviolet curing, which has the advantages of wear resistance, corrosion resistance, and easy cleaning.

During the container loading process, it is particularly important to ensure the following:

1.Packaging safety: UV board should be wrapped with appropriate packaging materials to prevent scratching or damage during transportation.

2.Loading specifications: Follow the correct loading procedure to ensure that the board is placed smoothly and avoid movement or tilting during transportation.

3.Complete documentation: Ensure that all necessary logistics documents, such as packing lists, bills of lading, commercial invoices, etc., are fully prepared and accurate.

4.Tracking logistics: Maintain communication with logistics companies, track the transportation status of goods, and ensure the safe arrival of goods at their destination.

After completing container loading, we will promptly notify customers of shipping information, including estimated arrival time, logistics tracking number, etc., to provide a good customer experience.

What are the advantages of UV board??

UV board, which is a decorative board treated with ultraviolet curing, has various advantages, making it widely favored in the fields of indoor decoration and furniture manufacturing. The following are the main advantages of UV board:

Wear resistant and scratch resistant: The surface of the UV board is treated with special ultraviolet curing to form a hard protective layer, which can effectively resist wear and scratches in daily use and maintain the smoothness of the surface.

Chemical resistance: UV board have good resistance to most acids, bases, and solvents, are not easily corroded, and are suitable for environments with frequent contact with chemicals such as kitchens and laboratories.

Easy to clean: The surface is smooth, not easy to absorb dust, and has strong anti fouling properties. It can be easily cleaned with a damp cloth or cleaning agent, and is easy to maintain.

Environmental protection and health: UV panels use low volatile organic compound (VOC) coatings in the production process, reducing the emission of harmful substances and meeting environmental standards, with minimal impact on human health.

Rich colors: UV panels can provide a variety of color and texture choices, from wood grain, stone grain to solid color, to meet different design needs and enhance decorative effects.

Fireproof and flame retardant: Some UV panels are made of flame-retardant materials, which have good fire resistance and increase safety.

Long service life: due to the high surface hardness and anti-aging, the UV plate has a long service life, reducing the replacement frequency and cost.

Easy installation: UV panels usually have a certain thickness and strength, making them easy to cut and install, and can be quickly applied to decorative projects such as walls and cabinets.

In summary, UV panels play an important role in modern decoration due to their excellent performance and beautiful appearance.